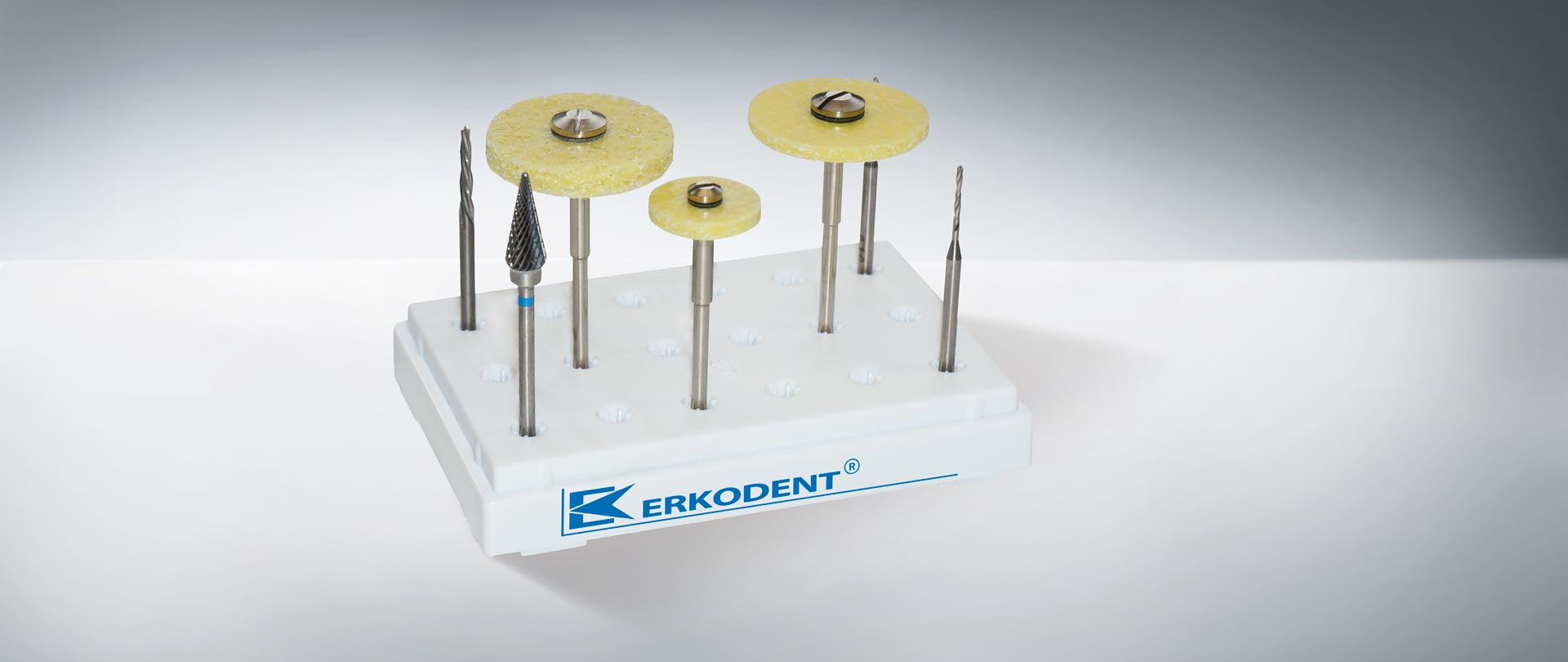

Finishing tools

To form and shine Erkoflex.

Crosscut conical tungsten carbide bur allows the quick grinding of small and large radius on all thermoforming materials.

Contains all rotating instruments that are useful for the finishing of all thermoforming materials: Fissure bur for rough cutting, HSS-twist drill for more precise contours, carbide bur for smoothing, Liskosil-l for prepolishing, removing larger amounts of material, without leaving an edged surface. Liskosil-m like Liskosil-l and for narrow areas, e.g. in the papilla area of a splint. Liskosil-s, for processing of occlusal interferences and

the inner surface of a splint.

The fissure bur is rightward cutting and has a left spiral. Material rests are transported away from the handpiece and therefore lumps during cutting are avoided. Used for rough cutting out of hard materials.

Fissure bur square made of steel. For rough cutting out of hard thermoforming foils and plates.

Hot-air-burner without flame, no soot, no blackening.

Lisko polishing discs with open structure for cooling, unique for working soft materials.

3 grain sizes: brown - coarse

grey - medium

white - fine

Lisko-B is a prepolishing discs with remarkably higher endurance. Lisko-B is always used with supporting discs on both sides. If the disc is ablated up to the supporting discs, these can be removed and the disc can still be used.

Lisko-S polishing discs have a half-open stabilized structure.

Liskoid is a stable pressed disc (DBGM), ideally suited for prepolishing narrow spaces of thermoformed splints.

Liskosil-l, diametre app. 27 mm, thickness app. 4 mm, is particularly suitable for large-area processing. Larger quantities of material can be removed without leaving an edgy surface.

Liskosil-m, diametre app. 27 mm, thickness app. 2 mm, allows the same result as Liskosil-l in narrow areas, e.g. in the papilla area of a splint.

Liskosil-s, diametre app. 16 mm, thickness app. 2 mm. The small diametre allows the processing of occlusal interferences and even of the inner surface of a splint.

Liskosil start set, one disc each of Liskosil -s (approx. 16 mm diameter and 2 mm thickness), Liskosil -m (approx. 27 mm diameter and 2 mm thickness), Liskosil -l (approx. 27 mm diameter and 4 mm thickness) and 3 mandrel

Polishing disc out of linen.

Set to polish hard thermoforming materials with the techical handpiece.

To fix and remove the Silensor®-sl components

The special polishing mass is made for hard thermoforming materials, but is also suited to polish other hard plastics.

To cut out all soft thermoforming materials and hard foils up to max. 1.0 mm thickness.

Pliers for easily taking hard thermoformed splints off the model.

Coarsely crosscut tungsten carbide bur, suitable for a fast elaboration of Erkoplast PLA material.

Crosscut pear-shaped tungsten carbide bur to grind occlusal splints.

HSS-twist drill for more precise contours, for hard and semi-hard splints, for ex. out of Erkodur or Erkolen.

• diameter 1 mm

• higher resistance to rupture

Twist drill. 1,4 mm diameter