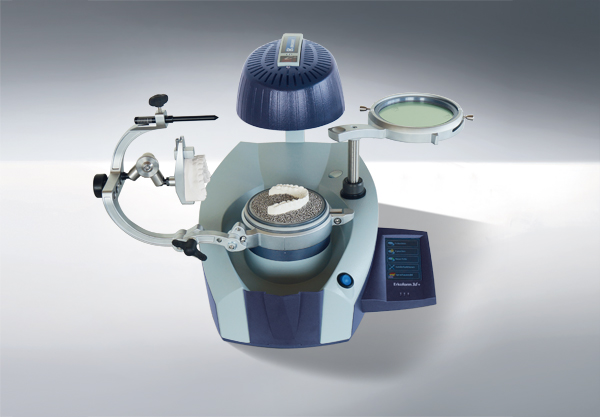

Vacuum thermoforming unit with automated thermoforming process.

Thermoforming units from the expert

Erkodent produces reliable vacuum and pressure forming units. High-quality thermoforming results will be achieved with the Erkodent vacuum units as well as with the pressure forming units. If you wish to also imprint the opposing bite during thermoforming in one working-step, we recommend the combination of an Erkoform vacuum unit (serie 3) and our integrable occludator Occluform-3.

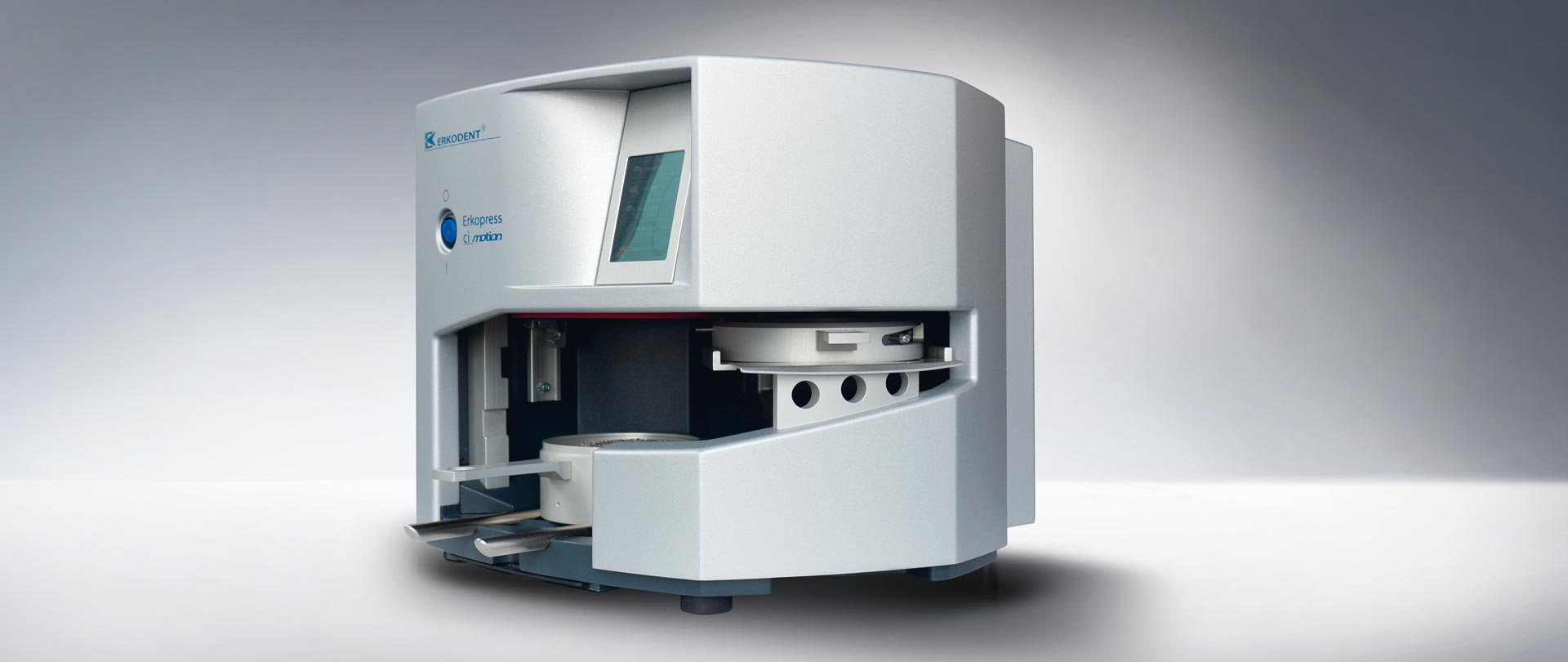

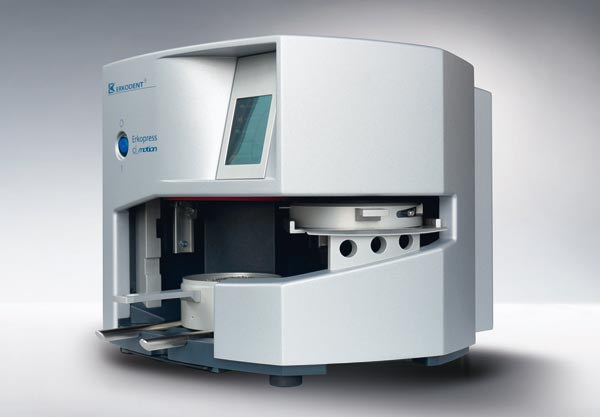

Erkopress ci motion

Pressure forming unit with automated thermoforming process with self-sufficient, integrated compressed-air production.

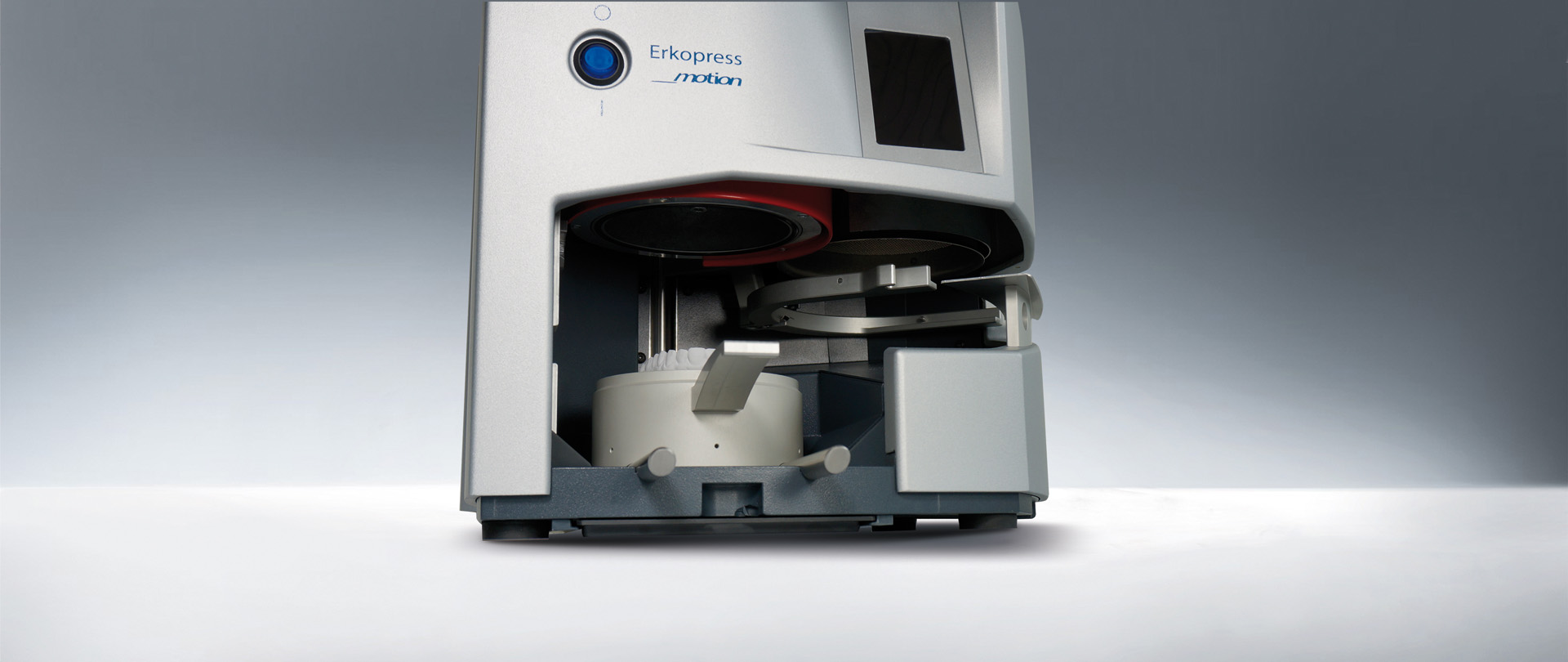

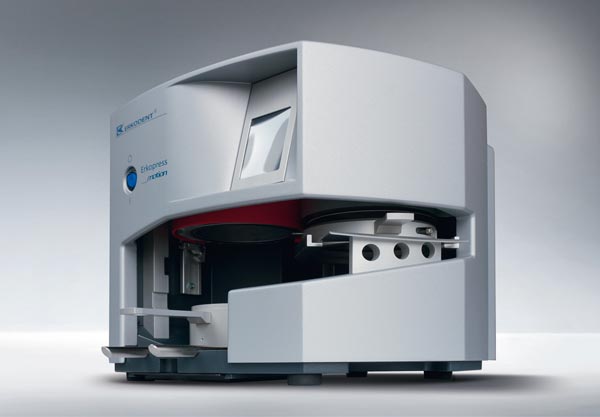

Erkopress motion

Pressure forming unit with automated thermoforming process to be connected to the existing compressed-air system.

| Erkoform-3d motion | Erkoform-3d+ | Erkopress motion | Erkopress ci motion | |

|---|---|---|---|---|

| Compressed air supply required | no | no | yes | no |

| Touchless temperature sensor | yes | yes | yes | yes |

| Medium-wave infrared heater | yes | yes | yes | yes |

| Preheating time | no | no | no | no |

| Reserve vacuum or reserve compressed air | yes | yes | no | yes |

| Foil thickness from 0 to 5.5 mm | yes | yes | yes | yes |

| Vertical prestretching and adaptiation | yes | yes | yes | yes |

| Delay free adaptation | yes | yes | yes | yes |

| Adjustment with Occluform-3 | yes | yes | no | no |

| Variable power for adaptation | no | no | yes | no |

| Touchpanel | yes | yes | yes | yes |

| All program features | yes | yes | yes | yes |

Thermoforming unit with automated thermoforming process.

A large volume reserve vacuum is being held to allow a sudden forming. A sensor for touchless temperature measurement ensures the accurate temperature of the material for the thermoforming regardless of the ambient temperature. The unit is equipped with a medium-wave infrared heating, which doesn’t need preheating time. The medium-wave allows for the materials to heat up not only on the surface but also in-depth. The result is a less stressed splint. The Occluform-3 can be installed (accessory).

• weight 13,9 kg

• foil diameter 120 mm

• foil thickness 0 - 5.5 mm

• ~220 - 240 (110 - 120) (100) volts, 50 - 60 hertz

• power: 340 watt

• max. vacuum 0.8 bar

• noise level < 60 dB(A)

• No compressed air supply required, plug and play.

• No preheating time needed.

• Touchless temperature sensor to exactly determine the actual temperature (patented) of the thermoforming material.

• Prior to the thermoforming process built up vacuum with sudden forming.

• Vertical pre-stretching and fitting for even foil thicknesses.

• To position the foil, with foil thicknesses of 0 to 5.5 mm, the unit can be operated conveniently with one hand.

• Easily accessible model during heating period.

• Acoustic and visual signal (suitable for people with impaired hearing).

The Erkoform-3d+ has the same characteristics as the Erkoform-3dmotion but without automated thermoforming process. Also the touchpanel functions are the same. A large volume reserve vacuum is being held to allow a sudden forming. A sensor for touchless temperature measurement ensures the accurate temperature of the material for the thermoforming regardless of the ambient temperature. The unit is equipped with a medium-wave infrared heating, which doesn’t need preheating time. The medium-wave allows for the materials to heat up not only on the surface but also in-depth. The result is a less stressed splint.

The Occluform-3 can be installed (accessory).

• weight 11,9 kg

• foil diameter 120 mm

• foil thickness 0 - 5.5 mm

• ~220 - 240 (110 - 120) (100) volts, 50 - 60 hertz

• power: 340 watt

• max. vacuum 0.8 bar

• noise level < 60 dB(A)

• No compressed air supply required, plug and play.

• No preheating time needed.

• Touchless temperature sensor to exactly determine the actual temperature (patented) of the thermoforming material.

• Prior to the thermoforming process built up vacuum with sudden forming.

• Vertical pre-stretching and fitting for even foil thicknesses.

• To position the foil, with foil thicknesses of 0 to 5.5 mm, the unit can be operated conveniently with one hand.

• Easily accessible model during heating period.

• Acoustic and visual signal (suitable for people with impaired hearing).

• The display informs about each operating status and the remaining time.

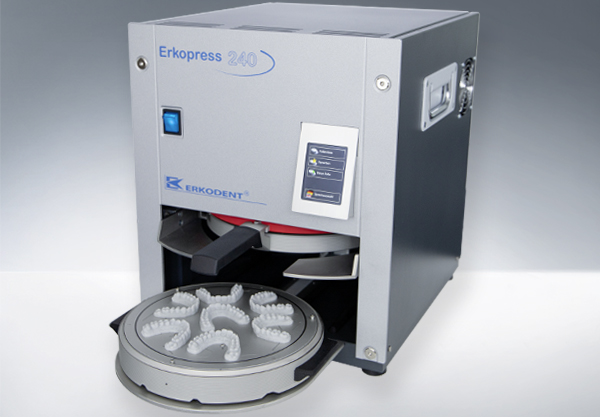

Pressure forming device with automated thermoforming process for up to 6 models with base and for up to 9 models without base, to connect with the existing compressed air system.

• The unit works with an overpressure of up to 4,5 bar. It thus meets the desire of many users to thermoform 3d print models with overpressure.

• weight 47 kg

• foil diameter 240 mm, thickness 0 - 2.0 mm

• operating voltage: ~220 - 240 (100, 110 - 120) volt, 50 - 60 hertz

• wattage: max. 1100 watt

• working pressure 4,5 bar, required mains system pressure > 6 bar

• noise level < 80 dB(A)

1 foil securing ring (179 015)

1 foil reception (179 010)

1 form pot with model disc support (179 005)

2 model discs (1 pcs. 179 020)

1 power supply cable (170 001)

1 hose connection

1 brush as an input pen

1 test foils

machine documents (folder), instructions, guarantee card

Pressure forming unit with automated thermoforming process

with self-sufficient, integrated production of compressed air. The Erkopress ci motion has a powerful, integrated compressor with reserve compressed air. Thereby the unit is independent of a compressed air system that possibly has to be installed.

• weight 21,3 kg

• foil diameter 120 mm

• foil thickness 0 - 5.5 mm

• ~220 - 240 (100, 110 - 120) Volt, 50 - 60 Hertz

• power: 440 watt

• noise level < 70 dB(A)

• working pressure 6 bar

• Place model • Everything else will be done by the device

• The thermoforming process as well as the cooling time will run automatically.

• Touchless temperature sensor to exactly determine the actual temperature (patented) of the thermoforming materials.

• For uniform wall thicknesses the hot foil will be placed vertically onto the model.

• The adaption is taking place without delay.

• Outstanding workplace safety through automatic switch-off function.

• Pinch protection during the automated thermoforming.

• The medium-wave infrared heating without preheating time, heats up the material not only on the surface but also indepth.

• Easily accessible model during heating period.

• Acoustic and visual signal (suitable for people with impaired hearing).

• Program-controlled function and process.

• The program contains all Erkodent thermoforming materials and as a quick guide, supported by animations, it leads through the workflow and signalizes the necessary work steps.

• Select the desired foil and thickness and start the process.

• Frequently used foils, new foils and even modified factory settings can be saved as favorites.

Pressure forming device with automated thermoforming process to connect with the existing compressed air system. The medium-wave infrared heating without preheating time, heats up the material not only on the surface but also in-depth.

• weight 18,9 kg

• foil diameter 120 mm

• foil thickness 0 - 5.5 mm

• ~220 - 240 (100, 110 - 120) Volt, 50 - 60 Hertz, max. 380 Watt

• power: 380 watt

• noise level < 70 dB(A)

• working pressure 6 bar

• Place model • Everything else will be done by the device

• The thermoforming process as well as the cooling time will run automatically.

• Touchless temperature sensor to exactly determine the actual temperature (patented) of the thermoforming materials.

• For uniform wall thicknesses the hot foil will be placed vertically onto the model.

• The adaption is taking place without delay.

• Outstanding workplace safety through automatic switch-off function.

• Pinch protection during the automated thermoforming.

• The medium-wave infrared heating without preheating time, heats up the material not only on the surface but also indepth.

• Easily accessible model during heating period.

• Acoustic and visual signal (suitable for people with impaired hearing).

• Program-controlled function and process.

• Air regulator with gauge and water separator

• The program contains all Erkodent thermoforming materials and as a quick guide, supported by animations, it leads through the workflow and signalizes the necessary work steps.

• Select the desired foil and thickness and start the process.

• Frequently used foils, new foils and even modified factory settings can be saved as favorites.

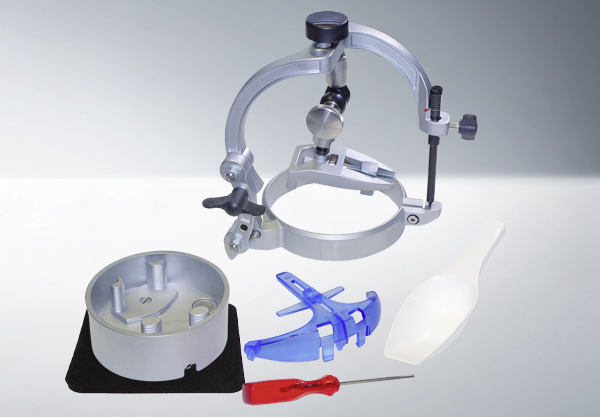

The Occluform-3 is an occludator that can be integrated in a thermoforming unit to imprint the opposing bite (pat. 19915567) and can only be installed at the Erkoform units serie 3.The construction of the Occluform-3 unit is based on a Bonwill triangle with side length of 11.5 cm and a Balkwill angle of 20°.

If a construction bite is at disposal the models are articulated in the Occluform-3 using this construction bite