Insert the foil

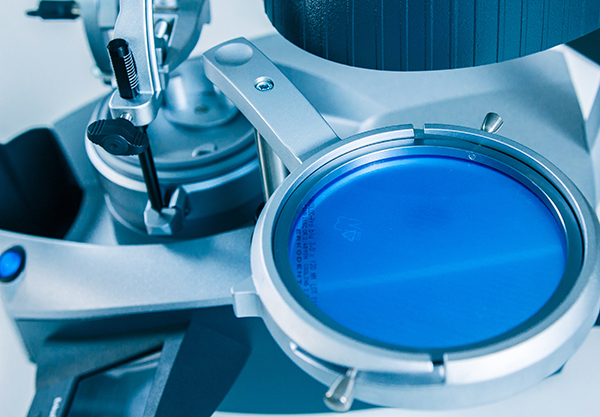

Erkoform-3d motion

Thermoforming unit with automated thermoforming process.

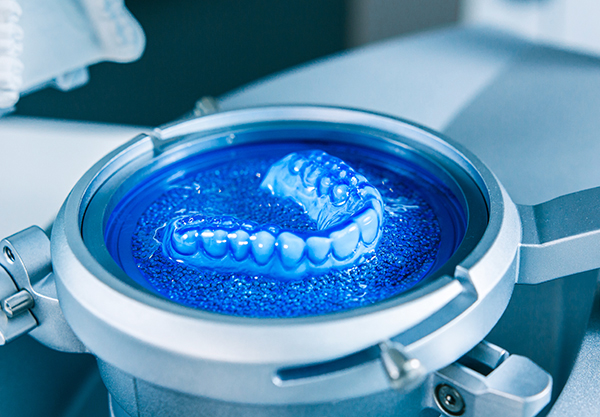

Occluform-3, fix the models

Articulate the models

Thermoforming temperature reached

Automated thermoforming process

Imprint …

… the opposing bite

Finished

3d motion in motion

Thermoforming unit with automated thermoforming process.

A large volume reserve vacuum is being held to allow a sudden forming. A sensor for touchless temperature measurement ensures the accurate temperature of the material for the thermoforming regardless of the ambient temperature. The unit is equipped with a medium-wave infrared heating, which doesn’t need preheating time. The medium-wave allows for the materials to heat up not only on the surface but also in-depth. The result is a less stressed splint. The Occluform-3 can be installed (accessory).

• weight 13,9 kg

• foil diameter 120 mm

• foil thickness 0 - 5.5 mm

• ~220 - 240 (110 - 120) (100) volts, 50 - 60 hertz

• power: 340 watt

• max. vacuum 0.8 bar

• noise level < 60 dB(A)

• No compressed air supply required, plug and play.

• No preheating time needed.

• Touchless temperature sensor to exactly determine the actual temperature (patented) of the thermoforming material.

• Prior to the thermoforming process built up vacuum with sudden forming.

• Vertical pre-stretching and fitting for even foil thicknesses.

• To position the foil, with foil thicknesses of 0 to 5.5 mm, the unit can be operated conveniently with one hand.

• Easily accessible model during heating period.

• Acoustic and visual signal (suitable for people with impaired hearing).